News

News Industry News

Industry News In industrial production and laboratory environments, leaks of combustible gases such as hydrogen, acetylene, and various organic vapors often pose extremely high safety risks. Timely and accurate detection of these gas concentrations is not only crucial for personnel safety but also essential for ensuring production continuity and equipment integrity. Therefore, Tensensor's ZC2529 catalytic combustion gas sensor, with its superior performance and reliable detection capabilities, has become the preferred solution for industrial gas monitoring.

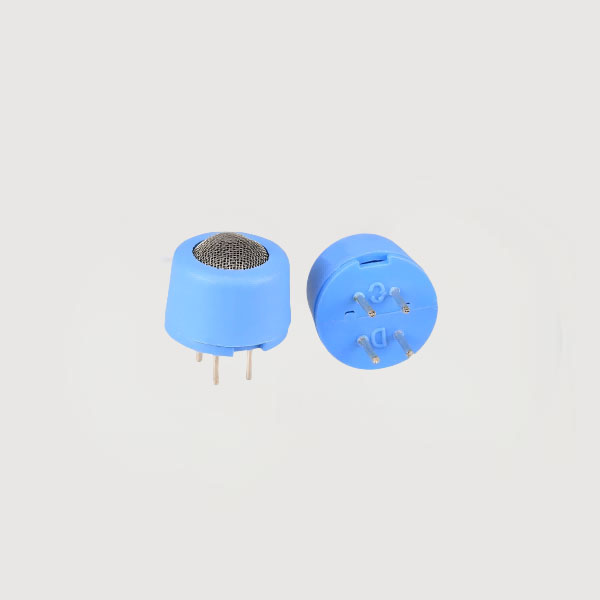

ZC2529 Catalytic Flammable Gas Sensor

Catalytic Combustion Principle, Precise Response to Combustible Gases

The ZC2529 sensor is designed based on the principle of catalytic combustion, consisting of a Wheatstone bridge composed of a detection element and a compensation element. When combustible gas comes into contact with the detection element, its resistance increases, causing a change in the bridge's output voltage, which is directly proportional to the gas concentration. The compensation element provides temperature and humidity compensation and serves as a reference, ensuring stable and reliable detection results.

This sensor is particularly suitable for leak alarm and concentration monitoring of hydrogen, acetylene, gasoline, and organic vapors such as alcohols, ketones, and benzene, and has the following outstanding features:

Linear Output: The bridge voltage has a good linear relationship with the gas concentration, facilitating system calibration and signal processing;

Fast Response: Response time (T90) ≤ 10 seconds, recovery time ≤ 30 seconds, timely detection of gas changes;

Strong Anti-interference: Excellent anti-interference capability against interfering gases such as hydrogen sulfide and organosilicon;

Strong Environmental Adaptability: Operating temperature range -40℃~+70℃, suitable for various industrial environments.

Solid technical specifications meet demanding industrial requirements

The ZC2529 sensor uses a plastic package, has a compact structure, and is easy to install. Its core parameters demonstrate excellent performance:

Operating Voltage: 2.5V±0.1V

Operating Current: 100mA±10mA

Sensitivity: 20-50mV for 1% hydrogen, 40-90mV for 1% acetylene

Measurement Range: 0-100% LEL (Lower Explosive Limit)

Lifespan: ≥2 years

The sensor exhibits outstanding long-term stability, with zero-point and sensitivity drift of less than 2mV per year, making it suitable for long-term continuous monitoring tasks.

Wide Application Scenarios, Safeguarding Safety in Multiple Industries

Petrochemical Industry: Monitoring flammable gases in reaction units, tank areas, and pipeline valve groups;

Laboratories and R&D Centers: Safety early warning for hydrogen and organic solvent usage environments;

Gas Stations and Refueling Stations: Leak detection of fuels such as acetylene and gasoline;

Painting, Printing, and other industries: Monitoring the working environment for organic vapors such as benzene series compounds and ketones.

Easy to use and maintain, supporting long-term stable operation

The sensor design balances practicality and reliability, supporting manual soldering. It is recommended to use low-chlorine rosin flux, with a soldering temperature not exceeding 350℃ and a soldering time not exceeding 5 seconds. To maintain sensor performance, exposure to silicon compounds, corrosive gases, water, ice, high-concentration gases, and severe vibration environments should be avoided.

For sensors stored for long periods, it is recommended to perform an aging process before use to ensure rapid recovery to a stable state.

The ZC2529 catalytic combustion gas sensor, with its high sensitivity, fast response, strong anti-interference capability, and good environmental adaptability, has become a reliable partner in the field of industrial combustible gas detection. Whether used in fixed alarm systems or portable detection instruments, it can provide users with continuous and accurate gas concentration information, helping enterprises achieve safe production and risk control.

For more technical details or purchasing inquiries, please contact Tensensor:

Web: www.tensensor.com

Email: [email protected]

WhatsApp: +86 18335818384