News

News Industry News

Industry NewsChoosing the most reasonable gas detection method depends on many factors, such as the type of gas to be detected, the detection accuracy requirements, the use environment, the cost budget, etc. In different application scenarios, how to choose the right sensor is a headache and requires certain professional nature. As a researcher in this industry, Tensensor has been committed to in-depth research in this area. We have compiled a simple description for different scenarios and implementation principles. The following introduces common gas detection methods and their applicable scenarios for you to make a suitable choice:

1. Electrochemical sensor detection

Implementation principle: The current generated by the oxidation or reduction reaction of the gas on the electrode is used to detect the gas concentration. Different gases react differently in specific electrode materials and electrolytes, and the magnitude of the current generated is proportional to the gas concentration.

Applicable scenarios: Suitable for detecting toxic gases such as carbon monoxide (CO), hydrogen sulfide (H₂S), sulfur dioxide (SO₂), etc. It is widely used in industrial environment monitoring, indoor air quality detection, underground coal mines, etc.

Advantages: High sensitivity, able to detect low concentrations of target gases; fast response speed, can monitor gas concentration changes in real time; relatively low cost, suitable for large-scale deployment.

Limitations: The sensor life is limited, generally 1-3 years; it is greatly affected by the cross-interference of ambient temperature, humidity and other gases.

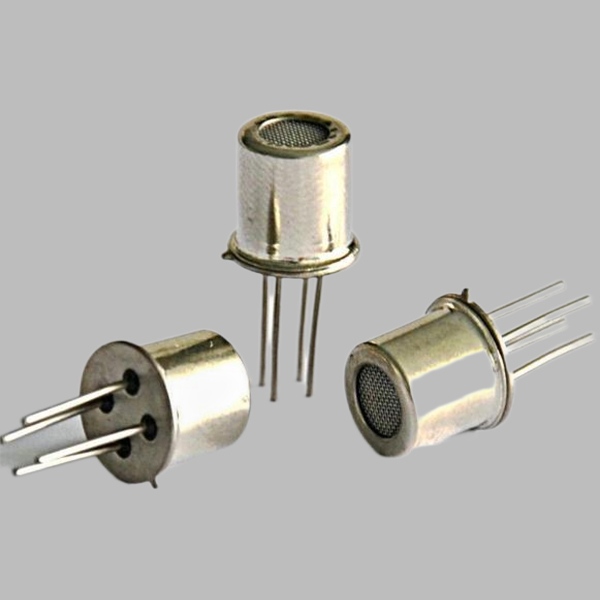

2. Catalytic combustion sensor detection

Implementation principle: Based on the combustion of combustible gas under the action of catalyst to generate heat, the resistance of the detection element changes, and the gas concentration is determined by measuring the resistance change.

Applicable scenarios: Mainly used to detect combustible gases, such as methane (CH₄), propane (C₃H₈), etc., commonly used for combustible gas leak detection in petrochemical, coal mines, gas pipelines and other places.

Advantages: High sensitivity and good linearity for combustible gas detection; fast response speed, can quickly detect combustible gas leaks; good stability and relatively long service life.

Limitations: Can only detect combustible gases, no response to non-combustible gases; "poisoning" may occur in a high concentration of combustible gas environment, resulting in a decrease in sensor sensitivity.

3. Infrared absorption sensor detection

Implementation principle: Different gases have absorption characteristics for infrared light of a specific wavelength. The gas concentration is determined by measuring the attenuation of infrared light after being absorbed by the gas.

Applicable scenarios: Suitable for detecting gases with infrared absorption characteristics such as carbon dioxide (CO₂) and methane (CH₄). It is widely used in greenhouse gas monitoring, industrial process control, indoor air quality monitoring and other fields.

Advantages: Good selectivity, able to distinguish different gases; high detection accuracy, wide measurement range; not affected by oxygen concentration, high stability and reliability; long service life, low maintenance cost.

Limitations: High instrument cost; sensitive to impurities such as dust and water vapor in the gas, which may affect the measurement results.

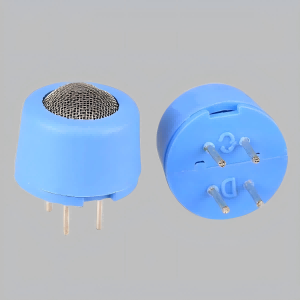

4. Semiconductor sensor detection

Implementation principle: The gas concentration is detected by using the characteristics of the electrical properties (such as resistance, conductivity, etc.) of semiconductor materials changing when they come into contact with gas.

Applicable scenarios: Commonly used to detect combustible gases, toxic and harmful gases and some volatile organic compounds (VOCs), such as formaldehyde (HCHO), ethanol (C₂H₅OH), etc. It is widely used in household gas alarms, indoor air quality monitors and other equipment.

Advantages: High sensitivity and fast response speed; low cost, small size, easy to integrate; has a certain response to multiple gases, and can realize multi-gas detection.

Limitations: Poor selectivity, easily interfered by other gases; relatively poor stability and repeatability, greatly affected by ambient temperature and humidity.

5. Laser scattering detection (for dust-like gases)

Implementation principle: When the laser irradiates the dust particles suspended in the air, the dust particles will scatter the laser, and the concentration and particle size distribution of the dust are determined by measuring the intensity, angle and other parameters of the scattered light.

Applicable scenarios: Mainly used to detect the dust concentration in the air, such as PM₂.₅, PM₁₀, etc., and are widely used in atmospheric environment monitoring, industrial dust emission monitoring, indoor air purification and other fields.

Advantages: Fast detection speed, real-time online monitoring; high measurement accuracy, can accurately measure low-concentration dust; can simultaneously measure the concentration and particle size distribution of dust.

Limitations: High equipment cost; high requirements for the optical system, requiring regular calibration and maintenance.

For more information about gas sensors, please feel free to contact us:

ShanXi TengXing Sensor Technology Co.,Ltd

Web: www.tensensor.com

Email: [email protected]