News

News Industry News

Industry News Commonly available dust sensors (also called PM2.5 sensors) fall into two main categories: infrared dust sensors and laser dust sensors. Both infrared and laser dust sensors can accurately measure the concentration of particulate matter in the air. What are the differences between them? A comparison can be made in the following aspects:

Structure and Principle

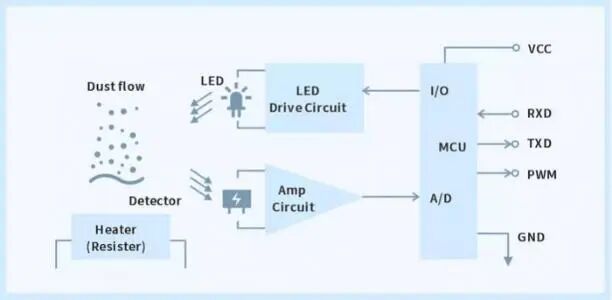

Infrared Dust Sensor

The structure of an infrared dust sensor is relatively simple. Its light source is an infrared LED. Based on the principle of light scattering, the light emitted by the LED is reflected when it encounters dust. The photodetector detects the intensity of the reflected light and determines the dust concentration based on the magnitude of the pulse signal. When no dust is detected, the photodetector outputs a low pulse; conversely, when dust is detected, it outputs a high pulse.

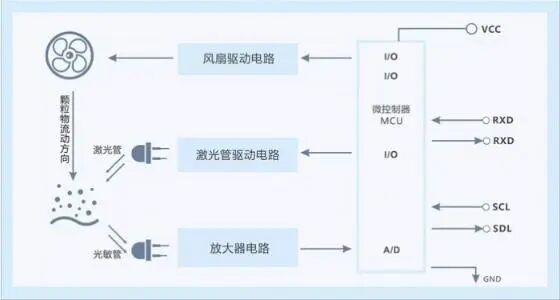

Laser dust sensor

Unlike infrared dust sensors, laser dust sensors incorporate a fan to generate stable airflow, allowing for rapid acquisition of PM2.5 concentration values in the environment upon activation.

Because they utilize laser LEDs as their light source, laser dust sensors have a more sophisticated structure and circuitry compared to infrared sensors. When fine particulate matter in the air is propelled into the laser beam area by a constant-flow fan, the laser light is scattered. A photodetector is placed at an appropriate location to receive only the scattered light. The photoelectric effect of the photodetector generates an electrical signal, which, after amplification and processing, yields the fine particulate matter concentration value.

Measurement Accuracy

Infrared dust sensors use infrared light sources with relatively long wavelengths (approximately 700-900nm), resulting in insufficient accuracy for measuring particles with an aerodynamic diameter smaller than 1µm. Because the particle signal scattered by infrared LED light is weak, it only shows a relatively significant response to larger particles (greater than 1µm). Furthermore, since it only uses a heating resistor to drive the sampling airflow, the sample size is small, leading to a measurement accuracy of approximately ±30%.

Laser sensors, on the other hand, can detect dust particles as small as 0.3µm. Because they incorporate a higher-performance MCU and use a constant-speed fan to increase airflow, they collect higher-density data, achieving an overall measurement accuracy of ±10%. Therefore, laser dust sensors have significant advantages over infrared dust sensors in terms of sensitivity, accuracy, and consistency.

Application

Due to insufficient accuracy, infrared sensors are mainly used for industrial and mining dust, detecting large-particle, high-concentration dust, and cannot accurately measure the concentration of PM2.5.

Laser dust sensors are primarily used in PM2.5 detection to accurately quantify PM2.5 levels. They can be embedded in home (vehicle-mounted, handheld) air quality monitors and air purifiers. Furthermore, laser-based sensors also have applications in IoT data acquisition and environmental quality monitoring.

Tensensor's dust sensors are widely used in dust detectors, air purifiers, fresh air systems, smart homes, air conditioners, and other fields. Please feel free to contact us if you have any needs.