News

News Industry News

Industry NewsDue to its high combustion efficiency and pollution-free products, hydrogen, along with solar energy and nuclear energy, is considered one of the three major new energy sources. As a new energy source, hydrogen is widely used in aviation, power generation, and other fields. Furthermore, as a reducing gas and carrier gas, hydrogen has extremely important applications in the chemical, electronics, medical, metallurgical, and particularly in the military and defense sectors. However, hydrogen molecules are very small and prone to leakage during production, storage, transportation, and use. Hydrogen is unbreathable, colorless, and odorless, making it undetectable to the human nose. Its ignition point is only 585°C, and its concentration in air ranges from 4.0% to 75.6%. It explodes when exposed to open flames. Therefore, hydrogen sensors are essential for detecting hydrogen levels in the environment and monitoring leaks.

Hydrogen sensor classifications and principles:

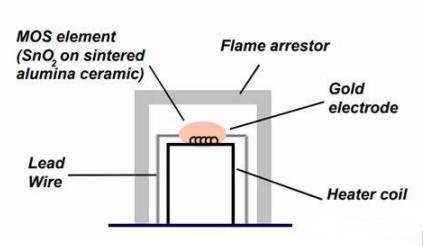

1. Metal Oxide Semiconductor (MOS) Hydrogen Sensor

A metal oxide semiconductor (MOS) hydrogen sensor consists of a heating resistor and a sensitive resistor made of a metal oxide layer deposited on the heater. The heating resistor heats the sensor to its operating temperature (200-500°C). The resistance of the metal oxide layer varies with temperature and the hydrogen content in the surrounding air.

2. Thermal Conductivity Hydrogen Sensor

Thermal conductive gas-sensitive materials measure gas concentration based on the difference in thermal conductivity between different combustible gases and air. Typically, this difference in thermal conductivity is converted into a change in resistance through an electrical circuit. Traditional detection methods involve introducing the gas to be tested into a chamber. At the center of the chamber is a thermal element, such as a thermistor, platinum wire, or tungsten filament, which is heated to a certain temperature. When the thermal conductivity of the gas to be tested is high, heat dissipates more easily from the thermal element, and its resistance decreases. The changed resistance passes through a signal conditioning and conversion circuit (a circuit that converts the electrical signal output by the sensing element into a useful signal for display, recording, and control), where it is converted into an imbalance by a Wheatstone bridge circuit.

A thermal conductivity gas sensor is an electronic gas sensor, a device or component that can sense a specific gas and its concentration in the environment. It converts information related to gas type and concentration into an electrical signal for detection, monitoring, analysis, and alarming. However, thermal conductivity gas sensors also suffer from drawbacks such as poor detection accuracy, low sensitivity, and large temperature drift in gas detection, limiting their widespread application.

3. Catalytic Combustion Principle

A catalytic combustion hydrogen sensor consists of two beads surrounding a wire operating at high temperature (450°C). One bead is passivated without a catalyst, preventing it from reacting when it comes into contact with hydrogen molecules and serving as a background reference. The other bead is coated with a catalyst to promote reaction with the gas. The beads are typically placed on separate legs of a Wheatstone bridge circuit. In the presence of hydrogen, the resistance of the catalytic bead increases, while the resistance of the passivating bead remains unchanged. This shifts the balance of the bridge and changes the output voltage Vout.

4. Electrochemical Hydrogen Sensor

Electrochemical hydrogen sensors (H2 sensors) operate on the same principle as fuel cells. They consist of an anode and cathode separated by a thin layer of electrolyte. When hydrogen passes through the electrolyte, a reversible chemical reaction occurs, generating a current proportional to the gas concentration. Electrochemical hydrogen sensors require very little power to operate, the lowest power consumption of all sensor types. Electrochemical hydrogen sensors feature high sensitivity, fast response time, excellent post-calibration reproducibility, good linearity, stable zero point, and relatively low crossover sensitivity. They are very useful in safety and process control applications.

The Tensensor's MQ-E3-H2 electrochemical H2 sensor is primarily used to detect hydrogen concentration in the atmosphere, with typical applications in the energy storage and chemical industries.